The next Tesla may come from Asia, with the potential to produce 36 million tons of biofuel annually from rice husk. Rice husk has long been treated as an agricultural waste product, despite its high energy content making it an ideal feedstock for producing biofuel. This article will explore the process of producing biofuel from rice husk, how biofuels compare to gasoline, and the importance of clean and renewable energy sources.

Rice is the world’s 3rd most grown crop, with the majority grown in Asia. 20% of the total rice mass is made of inedible husk, which is treated as waste. If processed correctly, we are capable of producing 36 million tons of biofuel annually from rice husk, the equivalent of 250 million barrels of crude oil. However, this amounts to just 28 days of U.S. gasoline consumption.

Sustainability Through Biofuels

The Fossil Fuel Issue

If you own a vehicle, you will quickly realize that a big part of your budget goes to paying for fuel. Cars, airplanes, and boats run on gasoline derived from fossil fuels like coal, natural gas, and petroleum excavated from deep within the Earth. Take a look at some vintage cars like Mercedes-Benz and Toyota AA, and you will realize how long we have been relying on fossil fuels for transportation alone.

Being a non-renewable source of energy—it takes millions of years for fossil fuels to form—we only have 50 years of fossil fuel supplies left. Furthermore, the burning of fossil fuels has contributed to global warming and climate change, causing irreversible damage to the environment. Scientists and innovators today are scrambling to find alternatives to fossil fuels. Besides hydropower and solar energy, biofuels are another form of renewable energy that is growing in prominence.

What is a Biofuel?

Biofuel is a renewable energy source from biomass (living matter like plants and animals). First, second, and third-generation biofuels come from edible plants, feedstocks, and algae, respectively. While burning biofuel does emit carbon dioxide and other greenhouse gases, they are produced from plants that remove carbon dioxide from the atmosphere, hence are considered a carbon-neutral source of energy.

Petroleum, on the other hand, is derived from carbon buried deep within the Earth. When used as fuel, petroleum combusts to add more carbon dioxide and other greenhouse gases to the atmosphere.

Corn ethanol, for instance, is a first-generation biofuel produced by fermenting corn grains and cobs. Because corn grains are also a food source, they are not the ideal raw materials. Instead, we can collect the uneaten cobs to make second-generation biofuels. Producing biofuel from inedible parts of a plant prevents a battle between food and fuel while turning what would be considered waste into a useful energy source.

Agricultural waste is an important feedstock in producing second-generation biofuels, especially from plants with high cellulose levels. Plants contain three naturally occurring and abundant polymers: lignin, cellulose, and hemicellulose. Among them, cellulose is the most ideal polymer for producing biofuel with.

Producing Biofuel From Rice Husk

Rice is a staple in many countries. In 2019, Asian countries produced a whopping 750 million tons of rice, accounting for almost all the worldwide rice harvest. The inedible husk (or rice hull) makes up 20% of the total weight of harvested rice, or 150 million tons.

Farmers typically consider rice husk a waste product. It is either thrown out or burned directly for heat. However, studies show that we can utilize the energy in rice husk more efficiently by converting it into biofuel in the form of ethanol. Ethanol can be used in cars, both directly and mixed with gasoline.

Producing biofuel from rice husk involves three steps:

- Extraction of cellulose from the rice husk

- Breaking down the cellulose into single glucose units

- Fermentation to convert glucose into ethanol

Extraction of Cellulose

The extraction of cellulose from biomass, also known as pretreatment, involves washing the rice husk with hot ethanol and water until it forms a pulp. This releases the cellulose from the rice husk, which amounts to 40% of its weight. This means around 60 million tons of cellulose by weight can be produced from rice husks annually.

The use of ethanol and the high temperatures required for this step are not ideal if we want to compete with the highly cost-effective extraction of fossil fuels. In a study published in 2014, a group of researchers used a simple procedure of pH treatment and bleaching to extract cellulose from rice husk without the need for heating. Further studies are required to bring the economical and environmental cost of this extraction step down.

Breaking Down Cellulose into Glucose

Cellulose is a polymer, meaning it is a long chain of glucose molecules, as shown in the diagram below. The bonds between glucose in cellulose are strong, however, requiring harsh treatments and organic solvents to cleave. As humans, our bodies are unable to break down cellulose, using it as dietary fiber. Even cows require four stomachs to digest cellulose efficiently!

Compared to the typical organic solvents, ionic liquids are more environmentally friendly while being easy to manufacture. In 2017, a research group showed that low-cost ionic (charged) liquids could be used to digest cellulose in plants at a 77% efficiency. In line with green chemistry principles, 99% of the ionic liquid used could also be recovered and reused for another round of cellulose breakdown.

Applying this to our 60 million tons of cellulose, we can produce 46 million tons of glucose from rice husks yearly.

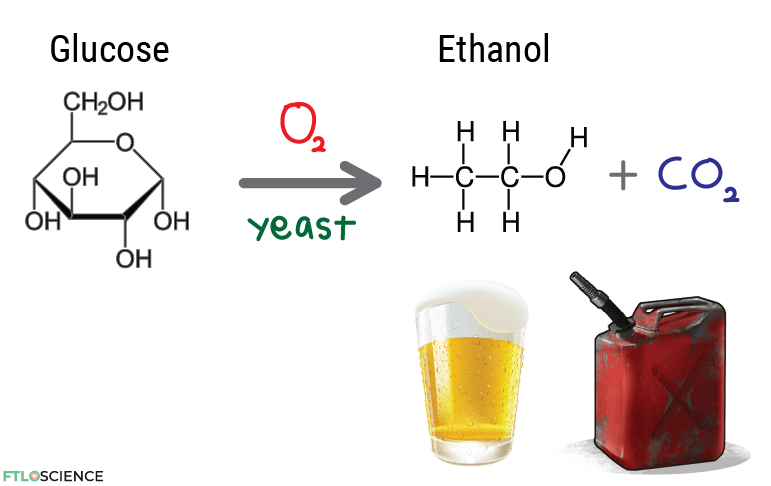

Converting Glucose into Ethanol

Finally, we can convert glucose into ethanol (a biofuel) through fermentation. This reaction involves glucose and oxygen reacting to form ethanol and carbon dioxide. Just like in the production of alcoholic drinks, the fermentation process is done using yeast (also used in baked goods). Under the right conditions, this process can achieve an 80% yield by mass.

With further research, we can apply similar methods to the ones outlined above to produce over 36 million tons of ethanol as biofuel from 150 million tons of rice husk every year, which equals an overall efficiency of 24%. In comparison, the process of converting crude oil to gasoline is 85% efficient, so we still have a way to go.

Ethanol as a Biofuel

Ethanol vs. Gasoline

Ethanol is the same alcohol found in beer, wine, and spirits. However, fuel-grade ethanol must be at least 99.2% pure, whereas ethanol mixed with drinking beverages is at most 50% pure. Of course, you wouldn’t want to pour any beer down your car’s fuel tank!

Fuel-grade ethanol has three notable advantages over gasoline: higher octane number, cleaner combustion, and lower price per gallon than unblended gasoline. A higher octane number corresponds to better fuel efficiency; ethanol has a better capacity to resist knock or auto-ignition better than gasoline. Ethanol also undergoes cleaner combustion than gasoline, reducing overall carbon by up to 48%. This number has the potential to increase with the development of more efficient farming and harvesting processes.

However, ethanol suffers in terms of energy density and its compatibility with older car models. Gasoline has a higher energy density as it contains more energy than the equivalent volume of ethanol. Energy density is an important factor, especially in transportation, where fuel is used to transport the weight of fuel in the vehicle. Ethanol alone doesn’t work in many cars, but up to 20% of ethanol in gasoline mixtures causes no issues in most engines.

36 Million Tons of Biofuel from Rice Husk

We’ve shown that we are capable of producing 36 million tons of biofuel from rice husk annually, presenting a massive opportunity for reaching our sustainability goals. The table below shows the efficiency and annual production of each step in the biofuel production process, from rice to ethanol.

| Material | Efficiency | Production (tons) |

|---|---|---|

| Rice | NA | 750 million |

| Rice Husk | 20% | 150 million |

| Cellulose | 40% | 60 million |

| Glucose | 77% | 46 million |

| Ethanol | 85% | 36 million |

36 million tons of ethanol is equivalent to 250 million barrels of crude oil, enough to supply the gasoline needs of the world for… around 6 days (44.5 million barrels/day, 2019 values). The U.S. for 28 days, China for 42 days, and India for 119 days. Those aren’t bad figures, considering rice husk is currently regarded as waste.

With enough support and traction, we can improve on Tesla’s mission to accelerate the birth of sustainable transport by using waste instead of electricity to power our vehicles. Farmers can gain more value for their hard work, and we can gain a cleaner and more sustainable environment. By producing biofuel from rice husk, we can show that rice fuels more than just our bodies!

About the Author

Marjory was a junior science writer at FTLOScience from October to November 2022.